Eileen Mountjoy

The story of the Ernest plant began in 1902, when officials of the Rochester & Pittsburgh Coal & Iron Company started looking to Indiana County in search of new coal fields.

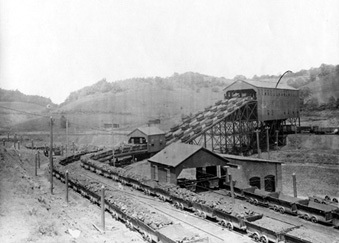

In May, 1903, the rails of the Buffalo, Rochester and Pittsburgh Railway reached the new town of Ernest, and the first coal was shipped the same month. From the early days of its existence, the Ernest plant was a marvel of engineering. In an era when most coal companies were dependent upon the lowly mule for motive power, the R&P's new operation utilized electric motors to haul coal to the steel tipple where a system of endless chains hoisted it up a long incline into the plant for cleaning and grading.

Within three years of its opening, the plant underwent the first of several renovations as the R&P constantly searched for more efficient mining and preparation methods to produce, clean, size, and market coal. In 1906, Heyl and Patterson of Pittsburgh constructed the first washing plant. This firm had also built the original tipple and most of the buildings used for coal storage and preparation at Ernest. The Fairmont Machinery Company and McNally-Pittsburgh also did important work for the R&P as the complex at Ernest expanded.

The R&P also established a coke industry at Ernest and eventually built a battery of 278 beehive coke ovens at the plant. Coke production figures from the Ernest ovens reflect general economic trends of the first half of the twentieth century as well as the effects of the later development of more sophisticated methods of making coke. By the mid-1920s, lack of demand for coke caused the temporary shutdown of the line of coke ovens at Ernest. The plant began production again in 1929, with the addition of mechanical unloading to replace the old hand drawing method. Annual production ebbed and flowed until a peak of 145,977 tons was reached during World War Two.

While the manufacture of coke formed a significant part of the activities at the Ernest plant, the mining, processing, and sale of clean fuel remained the prime factor in the success of the operation. In the early days, railroads, primarily the Buffalo, Rochester & Pittsburgh, consumed the greatest percentage of Ernest's coal. It was particularly desired as high grade stoker coal for passenger engines. By the mid-1920s, the original tipple had been remodeled, and a huge bin constructed for storage of clean, sized, coking coal. In the next decade, a "dry" plant for cleaning coal by air, and a wet" plant for cleaning coal with water, were installed at Ernest to bring the operation up to date.

By the beginning of World War Two, the Ernest coal plant began to resemble the plant best remembered by most Indiana Countians. As the war effort increased, Ernest kept pace with a growing need for coal; and, in 1945, the mining and preparation plant worked together to produce over a million tons of coal. In 1952, the McNally plant was built an the hillside behind the original site. Using a wet cleaning method to separate the coal from impurities, the McNally plant had a capacity of fifty tons per hour for coking coal. R & P later expanded this plant to clean four hundred tons per hour, and it contained all of the cleaning equipment used at Ernest.

By the early 1960s, R&P officials decided that coal could no longer be mined profitably at Ernest. In 1965, the plant was closed. Within a few years, equipment and buildings gradually disappeared from the landscape as scrap companies dismantled the mining operation that had taken over fifty years to construct. But the McNally preparation plant and the skeleton of the coking coal bin still remain on the blackened site. These, the foundations of the coke ovens, and a brick office and machine shop are all that survive of the R&P's Ernest operations, an Indiana County landmark to remember with pride.

The author would like to thank R&P Assistant Vice President of Operations, F. P. "Pete" Calhoun and the several members of the R&P engineering department who made suggestions and provided information about the many technical aspects of the Ernest mining operation.