The subject of crack propagation, which is related to the subject of how things break, is an important area of research in material science. Despite the technological importance of crack propagation the subject has, only recently, received some theoretical attention. This neglect occurred, partly, because the subject is too difficult to deal with (theoretically or experimentally). In part, this difficulty stems from the fact that the crack propagation is a non-equilibrium process. In fact, atoms near a crack tip are under tremendous amount of stress and moving so fast that the concept of temperature is not defined clearly. Many of the solid-state physics models are applicable to a perfect crystalline solid and do not apply to a crystal with a defect (crack). The main motivation for the study of crack propagation is because materials fail through the propagation of cracks.

With the advent of powerful computers, sophisticated molecular dynamics codes, and advanced visualization techniques it is now possible to tract the dynamics of the crack propagation in materials. A crack in a material includes a long-range strain/stress field. This indicates that for any computer simulation of the crack to converge, satisfactorily, a large number of atoms need to be included.

Materials are classified into two categories brittle or ductile. A brittle material shatters with a strike (like a glass), while in a ductile material, the strike causes it to deform (like a metal). In the brittle materials, the failure is believed to be due to the breaking of chemical bonds, while in ductile materials, the failure is believed to be due to the emission of dislocations. Most solids make a transition from a brittle to a ductile phase at a certain temperature. Presence of defects near a crack tip could lead to the strengthening of the material and prevent propagation of the crack tip.

A summary of some of the important questions concerning the crack propagation in materials are as follows: (a) What is the mechanism of crack propagation in a brittle material, (b) what is the mechanism of crack propagation in a ductile material, (c) can a crack propagate through breaking bonds in a material that is originally ductile, (d) is there a critical tensile load that will initiate the propagation of a crack, (e) what is the ultimate speed of a crack, (f) what kind of effects the defects have on the strength of a material, (g) what is the effect of interface on the propagation of the crack. In order to answer some or the entire above questions one need to employ an efficient molecular dynamics code coupled to a visualization tool.

The data generated by a molecular dynamics computer simulation of crack propagation includes positions and velocities of all the atoms in the system at each time step. The data can be fed into a graphic engine for visualization and animation. Due to the specific application at hand, one requires to consider a very large system size. However, most of the important dynamics take place near the crack tip and, therefore, majority of the atoms that are far away from the crack tip are doing the usual vibrations about their equilibrium sites. By visualizing only those atoms that are dynamically important (atoms near the crack tip), one could reduce the memory need as well as image processing time. The data generated from the simulation could be screened and store only those that are relevant to the atoms close to the crack.

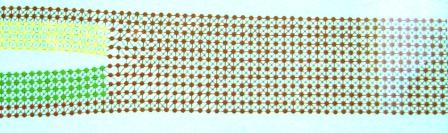

One improvement to the visualization/animation described in the previous paragraph is to map not only the propagation of the crack but also its temperature. This is important, because in most of the computer simulations of crack propagation, energy density deposited near the crack tip is so immense that could lead to the melting of the crack tip ( Holland 98). This is an unrealistic artifact of the interatomic interaction model that is employed in the simulation and can hardly occur in real crack propagation.